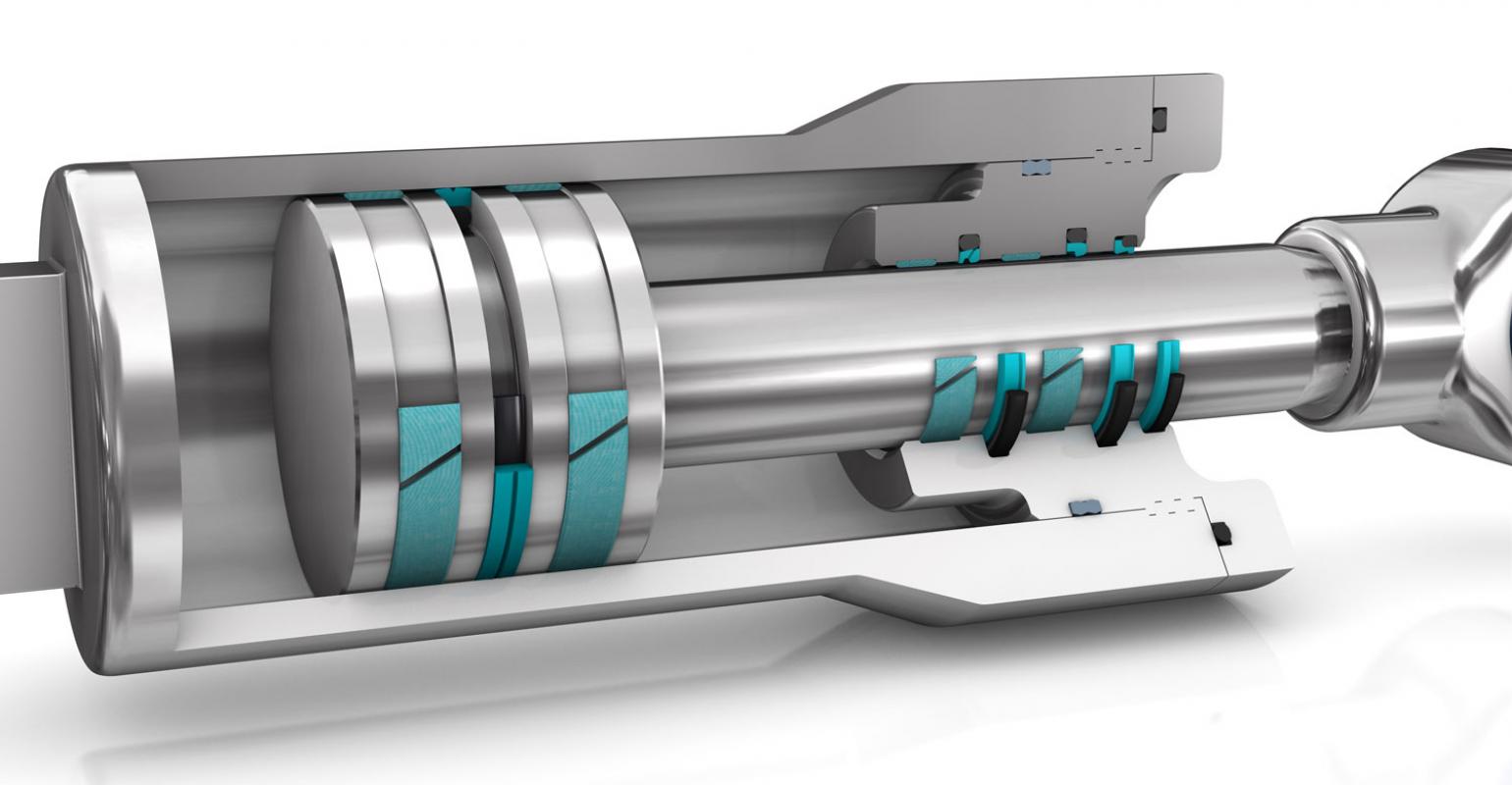

A hydraulic pistonis a component found within a hydraulic cylinder, which is used in countless applications across a variety of industries. Since hydraulic components are available in an array of scales, they can serve a wide range of needs. These cylinders are hard at work in industrial applications (hydraulic presses, balers, stump grinders, and packing machines) as well as mobile applications (agriculture, construction, and marine machines or vehicles).

Hydraulic systems tend to be simpler and more durable than pneumatic, mechanical or electric systems, which is why they are found in such a large number of applications. Hydraulics even offer more power density than these systems. When compared to an electric motor of the same size, a hydraulic pump can have about 10 times more power density.

Hydraulic cylinders and its components offer the most efficient method of lifting, pulling, pushing, and lowering available. It shouldn’t come as a surprise to see a hydraulic piston in operation in most machines. They are essential components that ensure safe, reliable operation of loaders, telehandlers, conveyors, shredders, and platforms along with pickers, platforms, rotators, drillers, choppers, and grinders.

Each application requires the right hydraulic components to ensure maximum performance and reliability. Many parameters and variables must be taken into consideration. However, with such a wide range of components and sizes available, finding the necessary components a hydraulics system isn’t a challenge.

When designing a hydraulics system, you must know the operating conditions in order to select the correct hydraulic pumps, cylinders, motors and other components. The hydraulic components selected for the machine must match the exact pressure, force, and space requirements. Once the operating requirements are met, half the battle has been won.

Other operating factors must be considered to ensure the correct materials of construction are used in the hydraulic systems. Certain machines may operate in extreme high or low temperatures, so the hydraulic piston and cylinder must be durable enough to withstand certain weather conditions. For instance, if temperatures exceed 300° F, standard Buna-N nitrile rubber seals will most likely fail. To prevent this from happening, try choosing cylinders with Viton synthetic rubber seals instead. Along with temperature, moisture must be accounted for in the selection of components. In the case of a marine hydraulic system, it may be exposed to humidity or saltwater.

Consider the following when selecting components for your hydraulic system:

- Maximum pressure range

- Cylinder movement

- Required tonnage

- Stroke length

- Mounting method

- Support requirements

Hydraulic systems, while incredibly efficient, are only as reliable as their individual components. Regardless of the application your hydraulic piston will be utilized in, always assume the operating conditions will be more rugged than originally imagined to potentially avoid any malfunctions in the future.

Leave a Reply