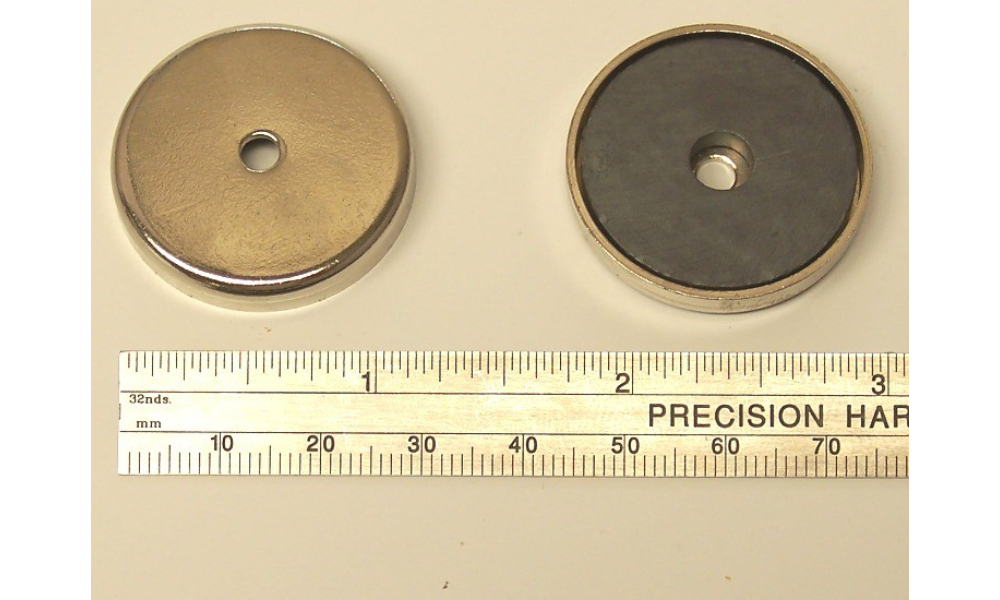

In modern industrial environments, efficiency, precision, and reliability are essential. One tool that continues to play a vital role across multiple industries is the round base magnet. Known for its compact design and powerful holding force, this magnet type—often manufactured using Rare Earth Magnets—supports a wide range of industrial tasks, from manufacturing to maintenance. Below are some of the top uses of round base magnets in industrial applications and why they are valued for performance and versatility.

Equipment Positioning and Alignment

One of the most common uses of a round base magnet is equipment positioning. In manufacturing and assembly lines, accurate alignment of tools, fixtures, or components is critical. Round base magnets provide a strong, stable hold that helps secure items in precise locations without the need for drilling or permanent fasteners. This allows for quick adjustments and improved workflow efficiency.

Holding and Securing Metal Components

Industrial operations often require temporary yet secure holding solutions. Round base magnets excel at holding metal parts in place during welding, cutting, or fabrication processes. Their concentrated magnetic force ensures stability, reducing the risk of movement that could affect accuracy or safety. When made with Rare Earth Magnets, these bases offer exceptional strength even in compact sizes.

Sensor and Instrument Mounting

Many industrial sensors, gauges, and measuring instruments need to be mounted securely while remaining easy to reposition. A round base magnet offers a non-invasive mounting solution that protects equipment and surfaces. Technicians can relocate devices quickly without damaging machinery, making maintenance and monitoring tasks more efficient.

Material Handling and Organization

In warehouses and production facilities, keeping tools and materials organized improves productivity. Round base magnets are frequently used to hold tools, cables, or metal components on workstations or machinery. This reduces clutter and ensures essential items are always within reach, saving time and minimizing downtime.

Automation and Robotics Support

Automation systems often rely on precise component placement and adaptability. Round base magnets are used in robotic setups to temporarily secure parts or fixtures during automated processes. The strength of Rare Earth Magnets ensures consistent performance, even in high-speed or repetitive operations.

Maintenance and Temporary Repairs

During equipment maintenance or emergency repairs, quick solutions are crucial. Round base magnets can be used to hold panels, covers, or components in place while repairs are performed. Their ease of use and strong holding power make them a reliable temporary solution in demanding industrial environments.

Testing and Quality Control Applications

In quality control settings, round base magnets help secure samples or testing equipment. Their stability ensures accurate measurements and consistent testing conditions. Because they can be easily repositioned, they offer flexibility during inspection and evaluation processes.

Conclusion

The versatility and strength of the round base magnet make it an indispensable tool in industrial applications. When combined with the power of Rare Earth Magnets, these compact solutions deliver exceptional performance for holding, positioning, and organizing metal components. From manufacturing floors to maintenance operations, round base magnets continue to support efficiency, safety, and precision across industries.

Leave a Reply