An assembly line is a procedure in which you would find various workers in a very common manufacturing approach are doing sequential production by completing one step or task of that product. The factory assembly line would provide your company with advantages on the economic scale and would help it a great deal to earn the name and ensure the quality of the product.

Also, if you are a start-up or a small or new business, you might be facing challenges regarding the production of physical products. This is one challenge that you need ways to fight off mainly with cost-efficient methods. This would help in the production of a good of higher quality products at a lower cost.

Producing products with the help of hand might be adequate at the beginning of your business initial days but as the demand would grow, the kv would save you a lot efficient and economic wise. There are several significant benefits that you would get to enjoy with the factory assembly line which has been mentioned below.

The specialization of Labour:

This would be a sequence of workers who would be given specific tasks on the production of a specific or multiple product. This would help in making the product reach the finished form faster.

The main feature of this would be that it allows the machines and the workers to specialize when it comes to performing a special task. This would amplify the output. This would allow for mass rate production that would not be possible if it was done by a single worker.

Uniform Product:

Another major benefit of using a factory assembly line would be that it is a regimented production process that would help you in coming out with a uniform product. Thus, this would help in maintaining uniformity and not a variation. Also, if otherwise, a worker creates a product from scratch it might be different from other worker’s finished goods.

High Cost-Efficiency:

This provides specific economies of social benefits. Each employee would be given a single role; therefore, the investment in training and development would be modest. Replication also ensures consistency, minimized defects as well as lower maintenance cost. Parts replacement would also be standardized and affordable. You would be able to provide better customer service.

Thus, these are some of the productive features behind going for a factory assembly line. This would also help in increasing efficiency and increase the production levels of your company as well for supplying during higher demand.

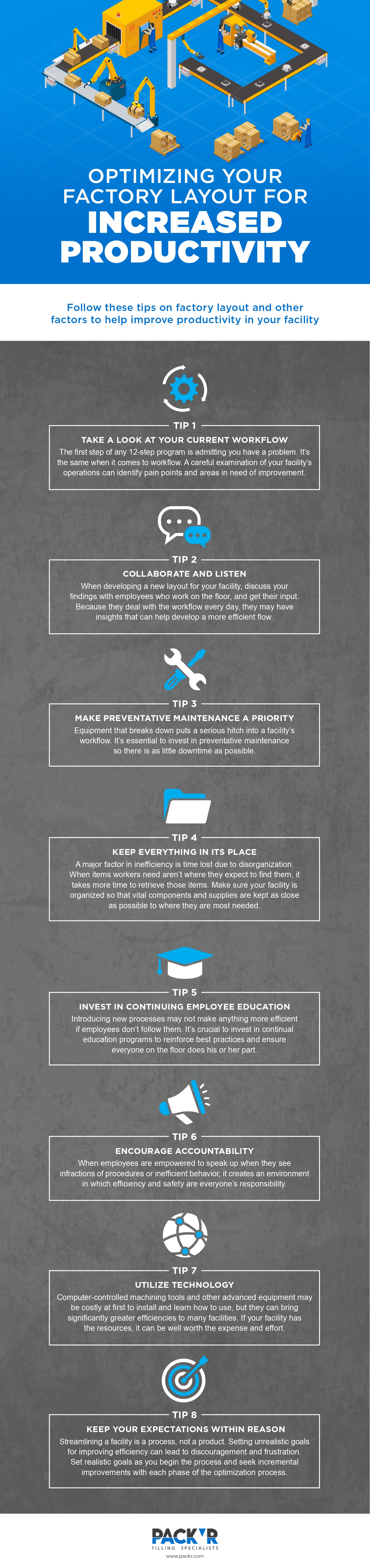

Assembly line implementation is only one way of optimizing your factory’s productivity. For more ideas, check out the infographic below!

Infographic provided by PACK’R, a food filling machine company